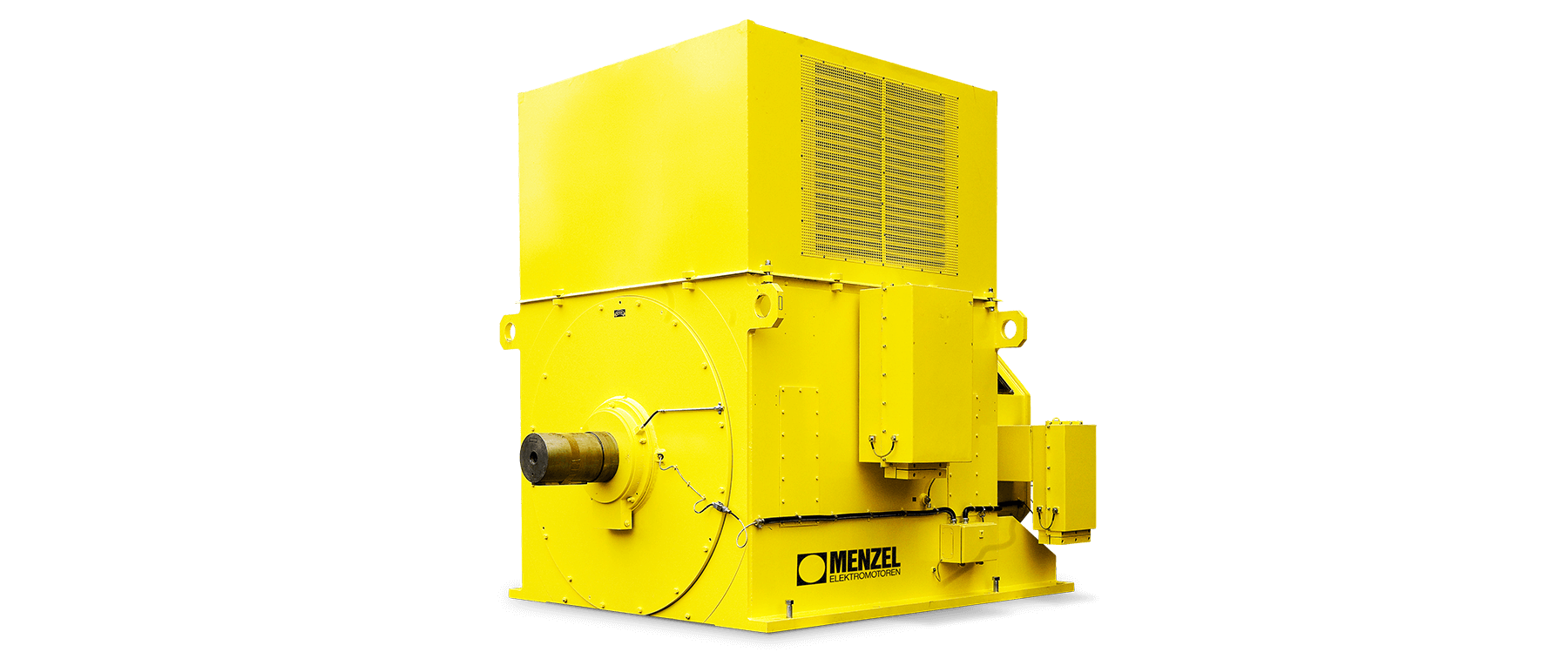

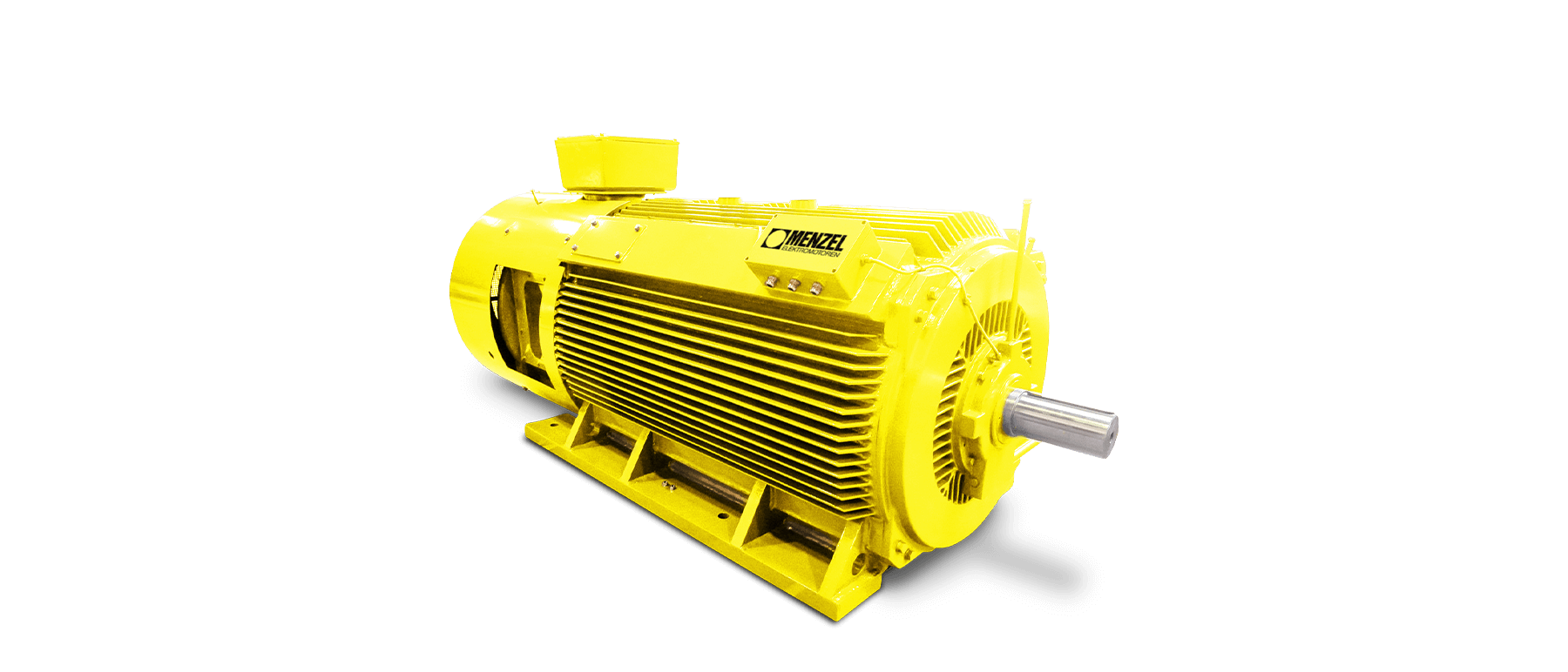

Modular slip ring motors

Modular slip ring motors from MENZEL are the ideal drive solution for industrial applications with high starting torques or low starting currents without the use of power electronics.

MENZEL slip ring motors are manufactured with a modular design for low, medium, or high voltage applications. This means that the electrical part of the motors is identical. This means reduced production costs, and at the same time, a sophisticated and proven design. The difference in slip ring motors mainly lies in the cooling system, which can be flexibly designed pursuant to your applications.

Our asynchronous slip ring motors are available as open-circuit ventilated (IC 01), surface-cooled (IC 411) or pipe-cooled (IC 511) motors, or with air-air heat exchanger (IC 611, IC 616 and IC 666) or air-water heat exchanger (IC 81 W). The choice of the correct cooling system depends on the application of the slip ring motor.

The following text introduces our modular slip ring motors in the MEBSSL series with air-air heat exchanger in the IC 611, IC 616 and IC 666 cooling classes.

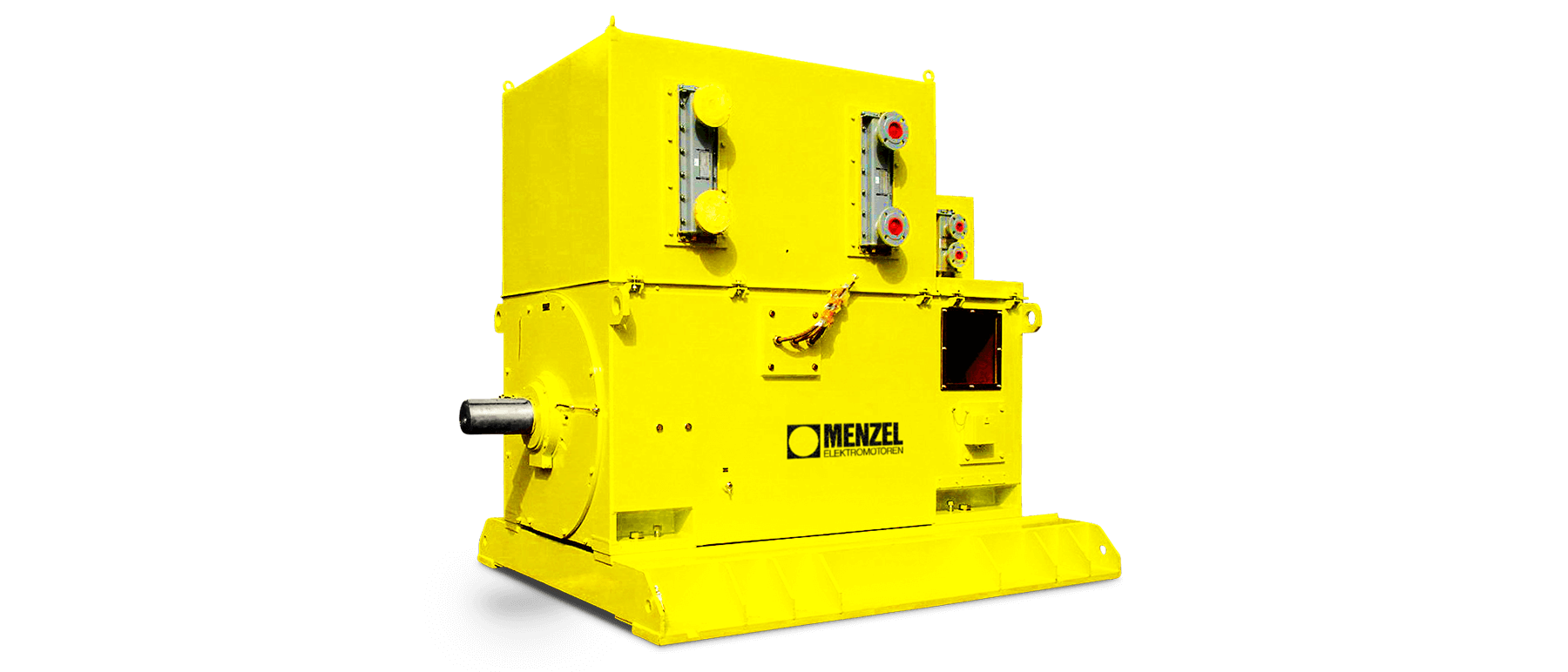

Standard design of modular slip ring motors with air-air heat exchangers (IC 611, IC 616, and IC 666)

- Construction types: IM B3, V1

- Protection classes: IP55, optionally IP65

- Voltage: from 230 V to 13800 V

- Power: up to 8000 kW

- Frame size: from 100 to 1000

- Terminal boxes: right or left, rotatable by 4 x 90°

- Motor housing: of welded steel with integrated footplates

- Thermal utilization: according to B or F Insulation class F, optionally H

Special designs of our slip ring motors with air-air heat exchanger in accordance with your specific specifications are possible at any time.

Available voltage ratings of our modular slip ring motors

Our modular motors with slip ring rotors are available for different nominal voltages. In addition, we can realize all special voltages and deviating voltage tolerances on request.

Nominal voltage at 50 Hz

- Low voltage: 220 V, 380 V /400 V, 500 V, 690 V

- Medium and high voltage: 3.000 V, 3.300 V, 5.000 V, 5.500 V/ 6.000 V, 6.300 V, 6.600 V, 10.000 V, 10.500 V, 11.000 V

Nominal voltage at 60 Hz

- Low voltage: 380 V, 400 V, 440 V, 480 V, 500 V, 525 V, 575 V, 690 V

- Medium and high voltage: 2.300 V, 4.160 V, 6.000 V, 6.600 V, 7.200 V, 11.000 V, 13.200 V, 13.800 V

The advantages of MENZEL modular slip ring motors

High level of efficiency and extremely low operating costs

Compact design, small size, and low weight

Reliable and durable bearing design

Good vibration values and low maintenance costs

Reliability and long product life

High load-bearing capacity

Low noise emissions

Customer-specific special designs

Modular slip ring motors with air-air heat exchanger - characteristics

MENZEL modular slip ring motors with air-air heat exchanger are in the MEBSSL series. They set technical standards with regard to frame size, performance, cost-effectiveness, and reliability. They are easy to maintain, have a robust design, and also have a long service life due to the inner slip ring chamber. This means they are ideally suited for drive operations under extreme operating conditions.

In order to prevent dust and dirt from getting inside the motor, the MEBSSL motors in the IC 611, IC 616 and IC 666 cooling classes are equipped with an enclosed cooling system in the form of an air-air heat exchanger. As the air-air heat exchanger and motor housing are decouple, installation and maintenance of these slip ring motors is particularly straight-forward. The construction also provides a large maintenance window for the slip rings. The inner slip ring chamber allows for the bearing to be replaced without disassembling the slip rings.

As is the case with all MENZEL electric motors, our modular slip ring motors are produced pursuant to European Standards EN 60034 and IEC 34.

Typical applications of MENZEL modular slip ring motors (IC 611, IC 616, and IC 666)

Typical user industries:

- Cement industry

- Food industry

- Process industry

- Power plants

- Paper industry

- Water and wastewater management

- Steel industry

- Raw material extraction and materials handling

Slip ring motors in the IC 611, IC 616, and IC 666 cooling classes are suitable for:

- Mill drives

- Refiner drives

- Shredder drive

- Compressor and compactor drives

- Fan drives

- Conveyor drives

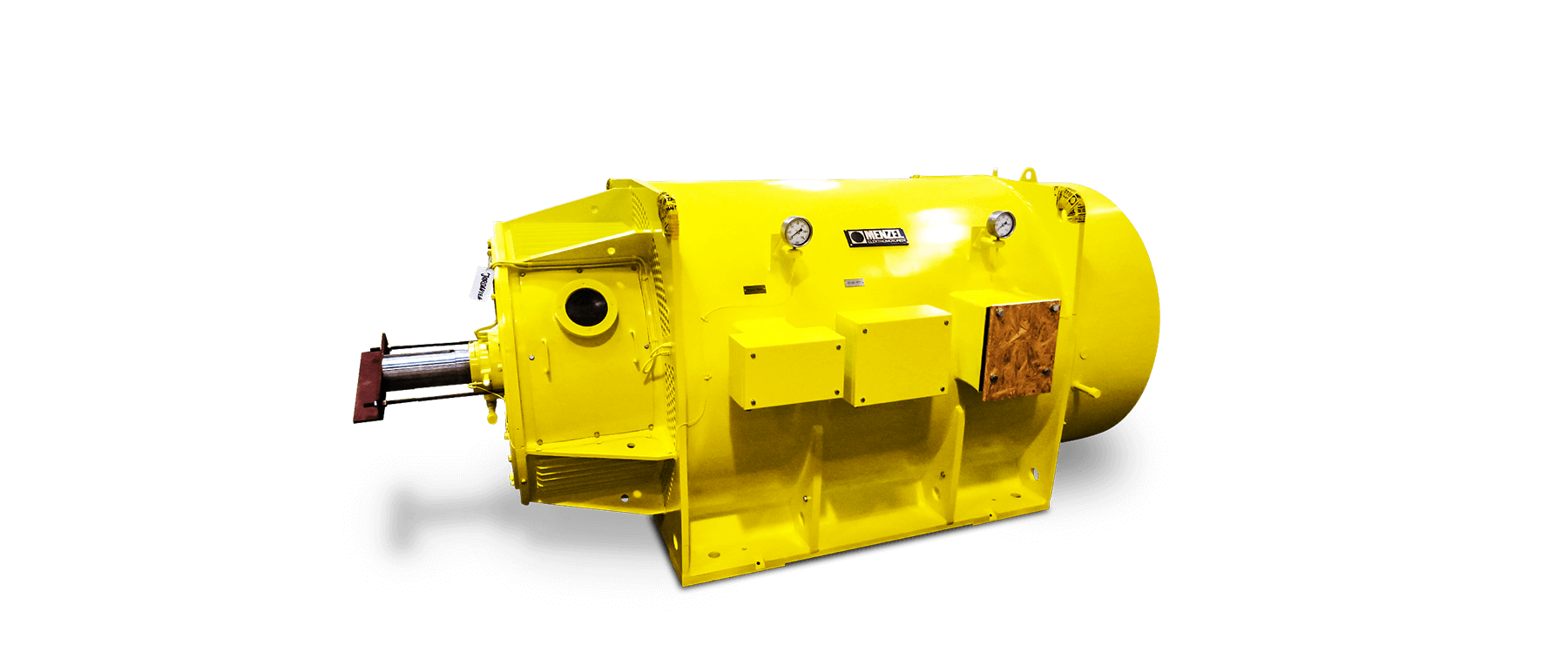

The principle of air-air cooling of slip ring motors (IC 611, IC 616 and IC 666)

The heat generated in the slip ring motor (stator and rotor) is fed into the air-to-air heat exchanger by an internal fan in the internal circuit. Ambient air from the exterior fan on the shaft flows through the air-air heat exchanger. The internal air transfers the heat generated to the cooling pipes which have ambient air flowing through them.

IC 611: Air-air cooling with wave fan in the internal and external circuit

IC 616: Air-air cooling with wave fan in the internal and forced cooling fan in the external circuit

IC 666: Air-air cooling with forced cooling fan in the internal and external circuit

Variants with regard to speed control, forced ventilation, or pipe connection with motors that run particularly slowly, can be delivered as a special design at any time. Air-air cooling in the IC 611 cooling class is still described as IC 0161 in older catalogs and product descriptions

Are you looking for compact slip ring motors for industrial applications under extreme conditions? Send us your inquiry! We have the right motor for you.