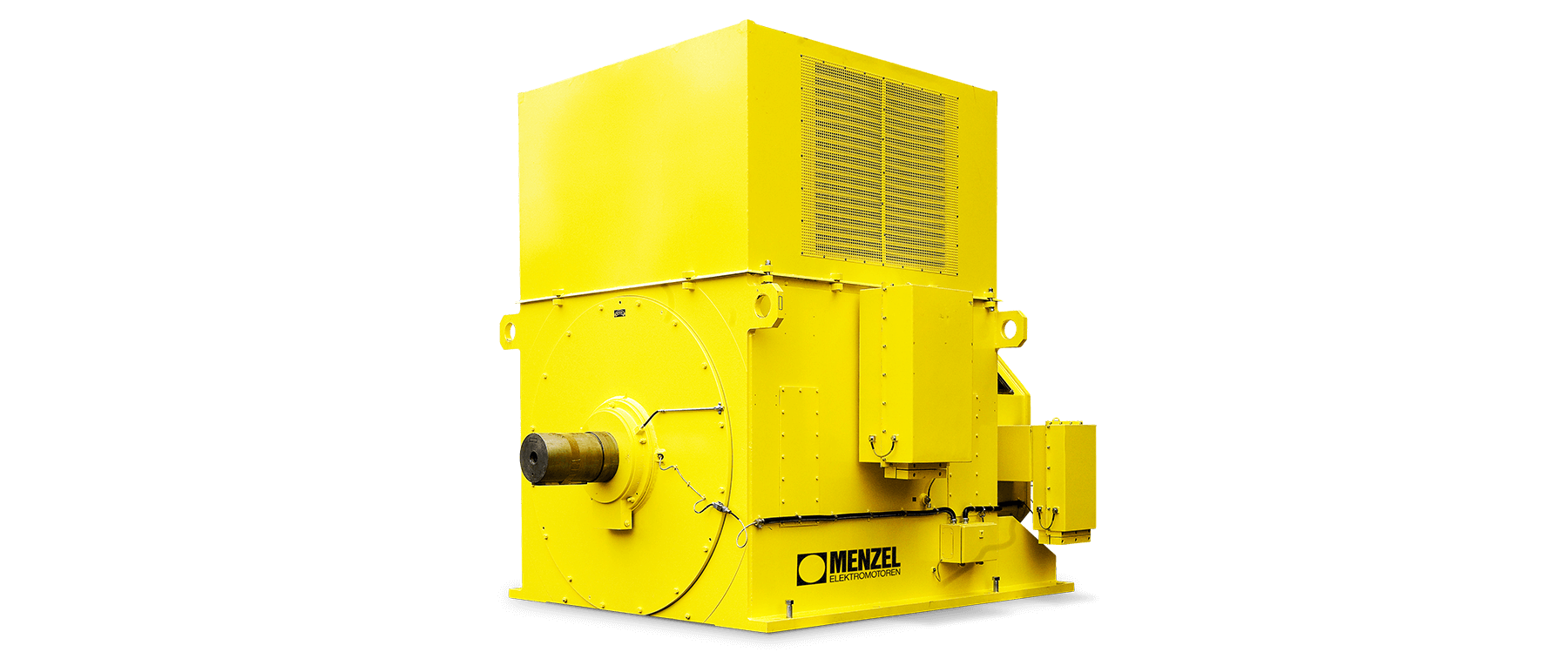

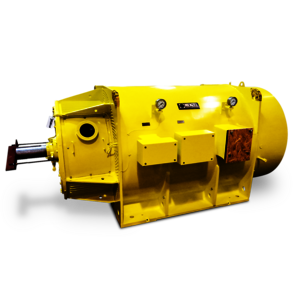

Low & high voltage slip ring induction motors

Since 1927 MENZEL has been an internationally renowned manufacturer of low & high voltage slip ring induction motors for all kinds of industrial applications.

MENZEL is a traditional manufacturer of three-phase asynchronous motors for low, medium, and high voltages. We have supplied industrial clients worldwide with large industrial motors since 1927. One of our primary focuses is the manufacture of customer-specific slip ring motors for high-performance drive applications.

MENZEL produces low & high voltage slip ring induction motors in a wide range of protection and cooling classes. We name our series after these. Manufacturing covers, amongst others, slip ring motors that are open-circuit ventilated (IC 01), surface-cooled (IC 411) or pipe-cooled (IC 511). In addition, we offer slip ring induction motors with air-air heat exchanger (IC 611, IC 616, or IC 666), or with air-water heat exchanger (IC 81W). The following article primarily focuses on the pipe or tube-cooled slip ring motors we manufacture, known as the MENZEL MEBSSH series.

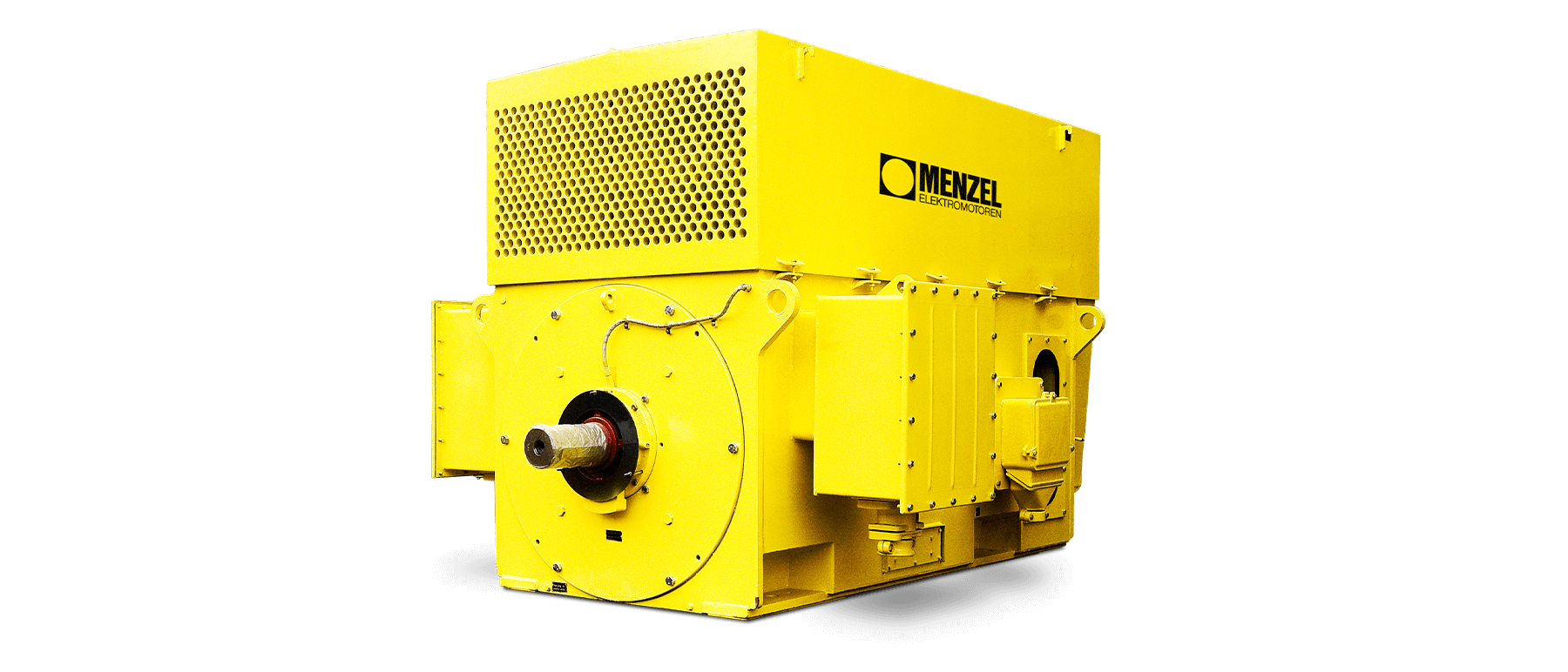

Standard versions of IC 511 slip ring motors in the MEBSSH series

- Construction types: B3 and V1

- Protection classes: IP 55

- Voltage: from 330 V to 13800 V

- Power: up to 4000 kW

- Frame size: from 450 to 900

- Motor housing: Welded steel

- Thermal utilization: F/B

MENZEL specializes in producing low & high voltage slip ring induction motors on custom-made products for industrial applications. We see ourselves as a solutions provider. Do not hesitate to contact us if your inquiry within the area of pipe-cooled slip ring rotor motors (IC 511) deviates from standard versions.

Available voltage ratings of MEBSSH series slip ring motors (IC 511)

Our pipe-cooled slip ring motors in the MEBSSH series can be delivered with the following nominal voltages as standard.

Nominal voltage at 50 Hz

- Low voltage: 380 V, 400 V, 500 V, 690 V

- Medium and high voltage: 3.000 V, 3.300 V, 5.000 V, 5.500 V/ 6.000 V, 6.300 V, 6.600 V, 10.000 V, 10.500 V, 11.000 V

Nominal voltage at 60 Hz

- Low voltage: 380 V, 400 V, 440 V, 480 V, 500 V, 525 V, 575 V, 690 V

- Medium and high voltage: 2.300 V, 4.160 V, 6.000 V, 6.600 V, 11.000 V, 13.200 V, 13.800 V

Advantages of IC 511 slip ring motors

Robust motor design resistant to external influences

Flat construction height and reduced overall length

Long machinery lifespan

High starting torque

Vibration resistant

Excellent, simultaneous air cooling

Simple to clean and maintain

IC 511 slip ring motors - characteristics

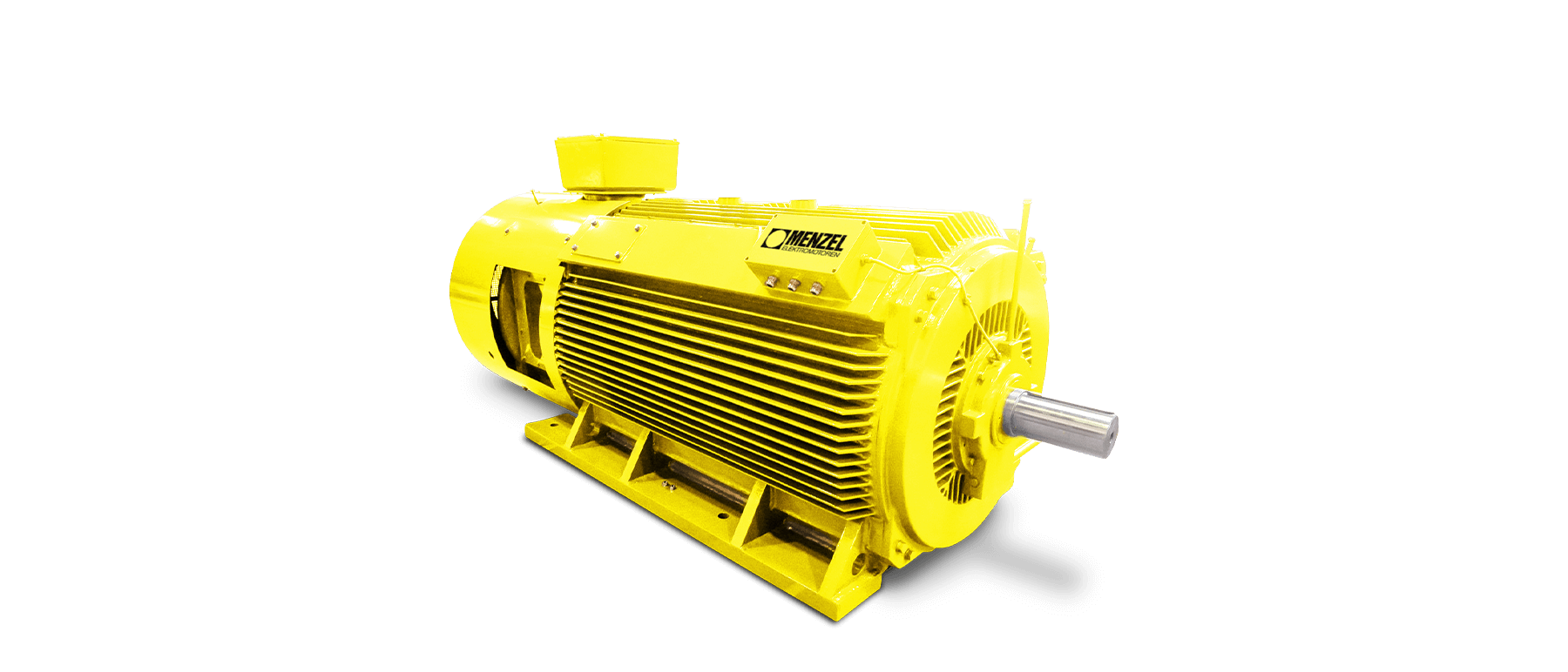

Slip ring motors are traditionally used for driving industrial machines, which require high starting torques with low starting current, or should start up smoothly. This is especially the case within the cement industry or in extracting raw materials. At the same time, these industries are exposed to a great deal of dust and dirt.

MENZEL slip ring motors in the IC 511 cooling class are designed with a separate inner slip ring chamber housing, which makes access and maintenance of these motors very simple. At the same time, IC 511 motors have excellent air cooling and are optimally protected against falling materials or other influences due to their rounded, smooth steel surface.

Our slip ring motors in the IC 511 cooling class consist of a hand-welded, torsionally rigid housing made of welded steel. Compared to the more common rib-cooled designs made of gray cast iron, these require a more sophisticated design, but offer considerable advantages especially in heavy-duty applications. For this reason, pipe-cooled IC 511 slip ring motors are especially robust against vibrations and shaking due to their design.

Typical applications of IC 511 slip ring rotor motors

Typical areas of use:

- Heavy-duty applications

- Mining

- Power plants

- Cement industry

- Raw material extraction, etc.

Pipe-cooled slip ring motors are used as:

- Conveyor belt drives

- Fan drives

- Kneader drives, etc.

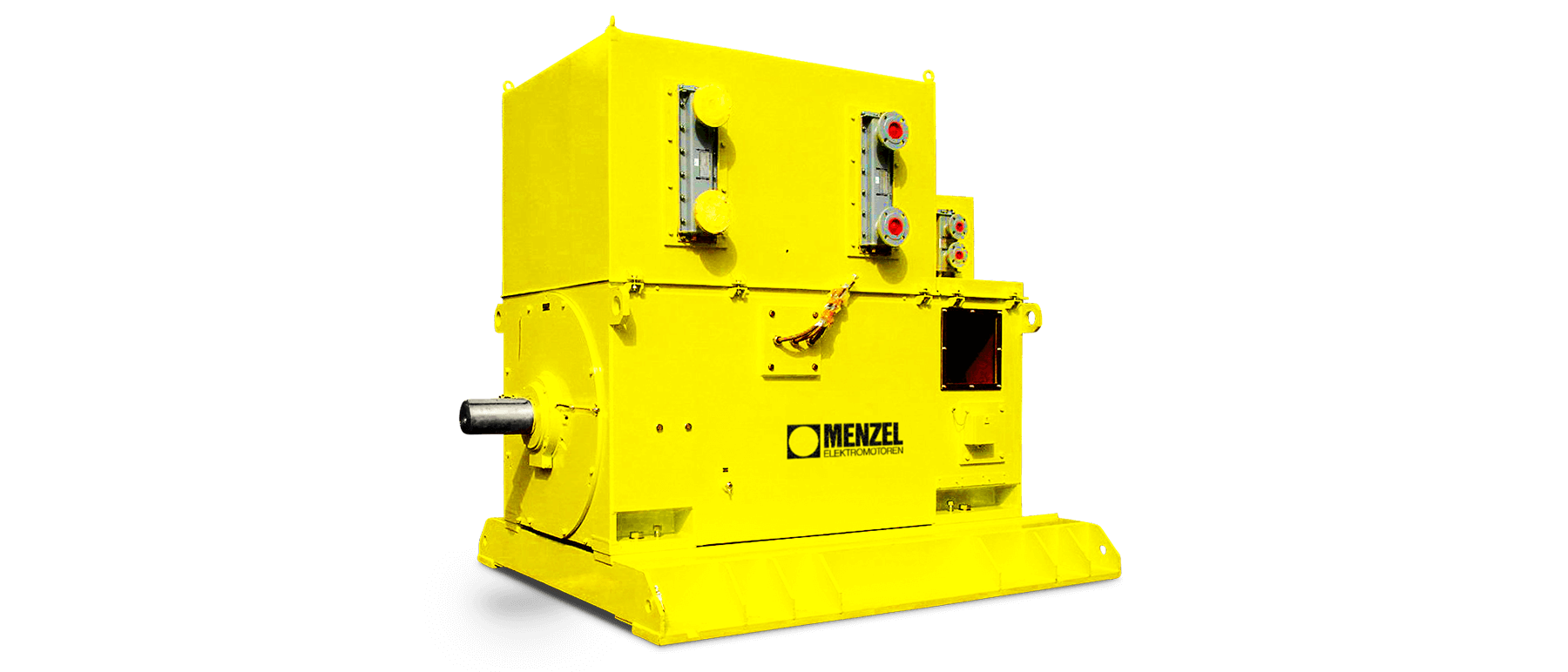

The IC 511 pipe cooling principle

The IC 511 pipe or tube cooling principle with our low & high voltage slip ring induction motors ensures particularly even and efficient cooling. In case of motors belonging to the IC 511 cooling class, tubes known as cooling tubes or cooling pipes pipes are symmetrically arranged around the laminated core. The primary and secondary coolants (air) are moved by fans on the motor shaft.

The big advantage of the straight airflow through the smooth cooling pipes is the extensive self-cleaning of the pipes due to the external coolant flow. As a result, the motors are less susceptible to the blocking of the cooling system. At the same time, the IC 511 pipe cooling principle enables a flat construction height and reduced overall length of the motors. Additional or forced ventilation of the motor is required.

Are you looking for low & high voltage slip ring induction motors directly from the manufacturer? MENZEL has produced and delivered slip ring rotor motors worldwide since 1927. Send us your inquiry today!