Custom 6600V electric motor for thermal power plant in Japan

MENZEL was asked to manufacture a custom 6600V electric motor to drive a multi stage condensate water pump in a thermal power station. The existing motor needed to be replaced quickly. In just four weeks MENZEL planned, built and delivered an three-phase squirrel cage motor with IC 616 cooling and IP 55 protection.

The requirements: Precision and speed

The customer not only wanted a motor that could be seamlessly integrated into the existing system via plug-and-play, but also one that could be implemented quickly. MENZEL was able to complete the motor in just four weeks.

One of our stock motors in the required size formed the basis. However, the following adjustments still had to be made:

Precision work on the rotor shaft: conversion to shaft nuts with left-hand thread and laser welding of the keyway.

Changing the cooling system: Conversion from IC81W to the IC616 system.

Adaptation of the direction of rotation: including different inner fan wheel Accompanying tests: Extensive tests in the load test field to ensure the highest standards.

Adapterplate and different mechanical modification: for a plug and play type fixing between the motor an the pump

The implementation: precision meets efficiency

During the planning phase, we went through several changes and special requirements. Thanks to the close cooperation between the customer, our project engineers and our production department, we were able to developand agree the technical solution quickly. Our ability to meet technical requirements and commercial details in record time was particularly praised. In addition, the motor was extensively tested in ourload test field. Where MENZEL successfully met all customer requirements.

Technical data of the AC-Motor

Type: MEBKSLF 500-04-011 AC-Motor

Motor application: Condensate water pump in a thermal power station

Rated power: 970 kW

Rated voltage: 6600 V

Rated speed: 1487 min-1

Type of construction: IM V1

Protection class: IP 55

Cooling type: IC 616

Weight: 7160 kg

The delivery: Precisely to the destination

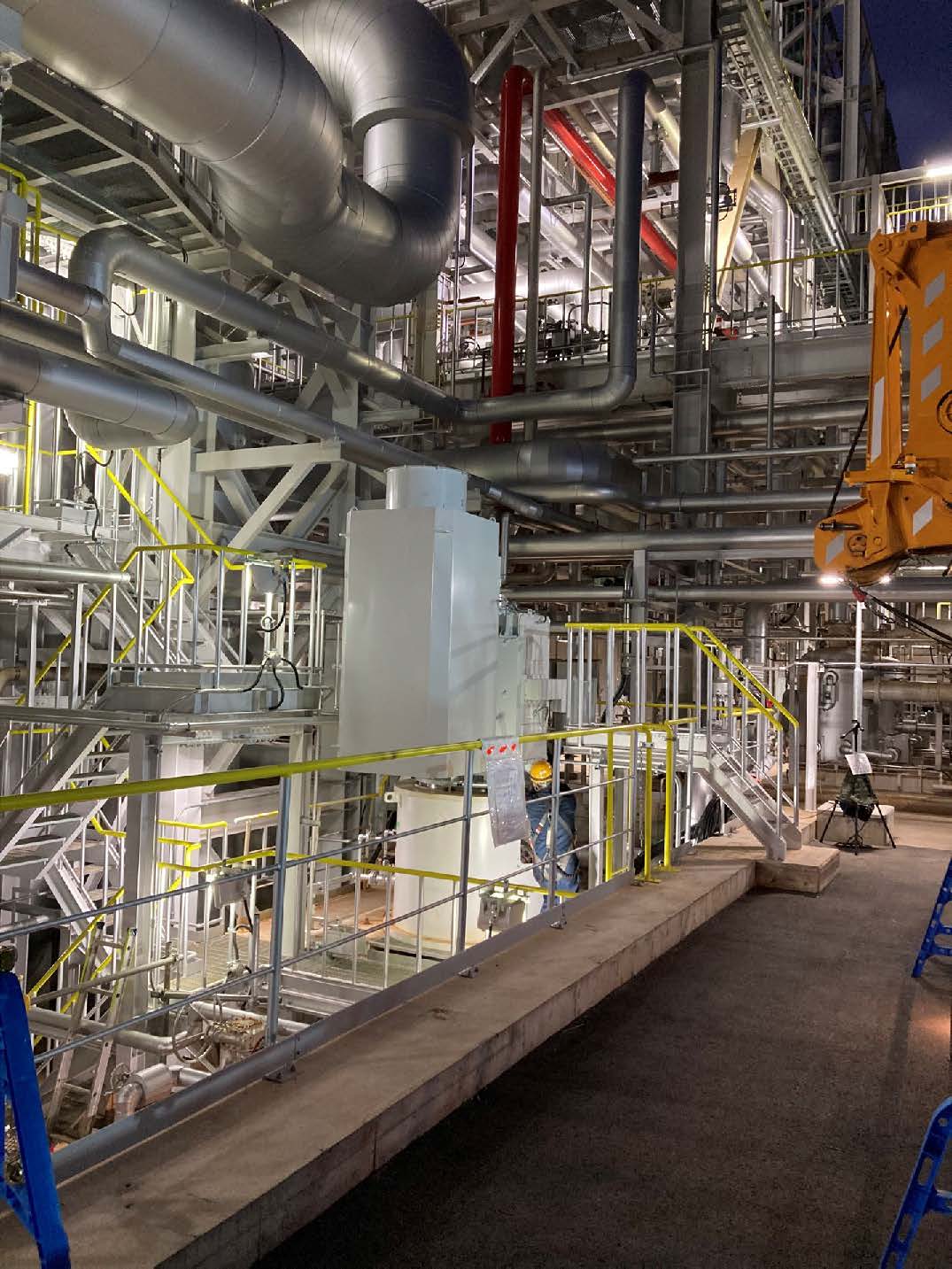

The finished squirrel cage motor was transported to Japan by plane in order to meet the critical deadline. Installation and commissioning took place at the thermal power plant, where the motor now reliably drives the multi stage condensate water pump.

This project is a prime example of our strengths:

✔ Custom solutions in the shortest possible time

✔ Efficient communication and close coordination

✔ Highest technical precision, made in Germany

Are you interested in further information or a customized motor offer? Send us your enquiry today!