One-Stop electric motors supplier – customized solutions

MENZEL offers electric motor single source supply in the high power range with full capabilities to also provide extensive additional services on request. By replacing an old motor from 1969, the water supply for around 250 towns and communities with around 3 million consumers was secured for the State Water Utility Baden Württemberg.

Here is the motor data:

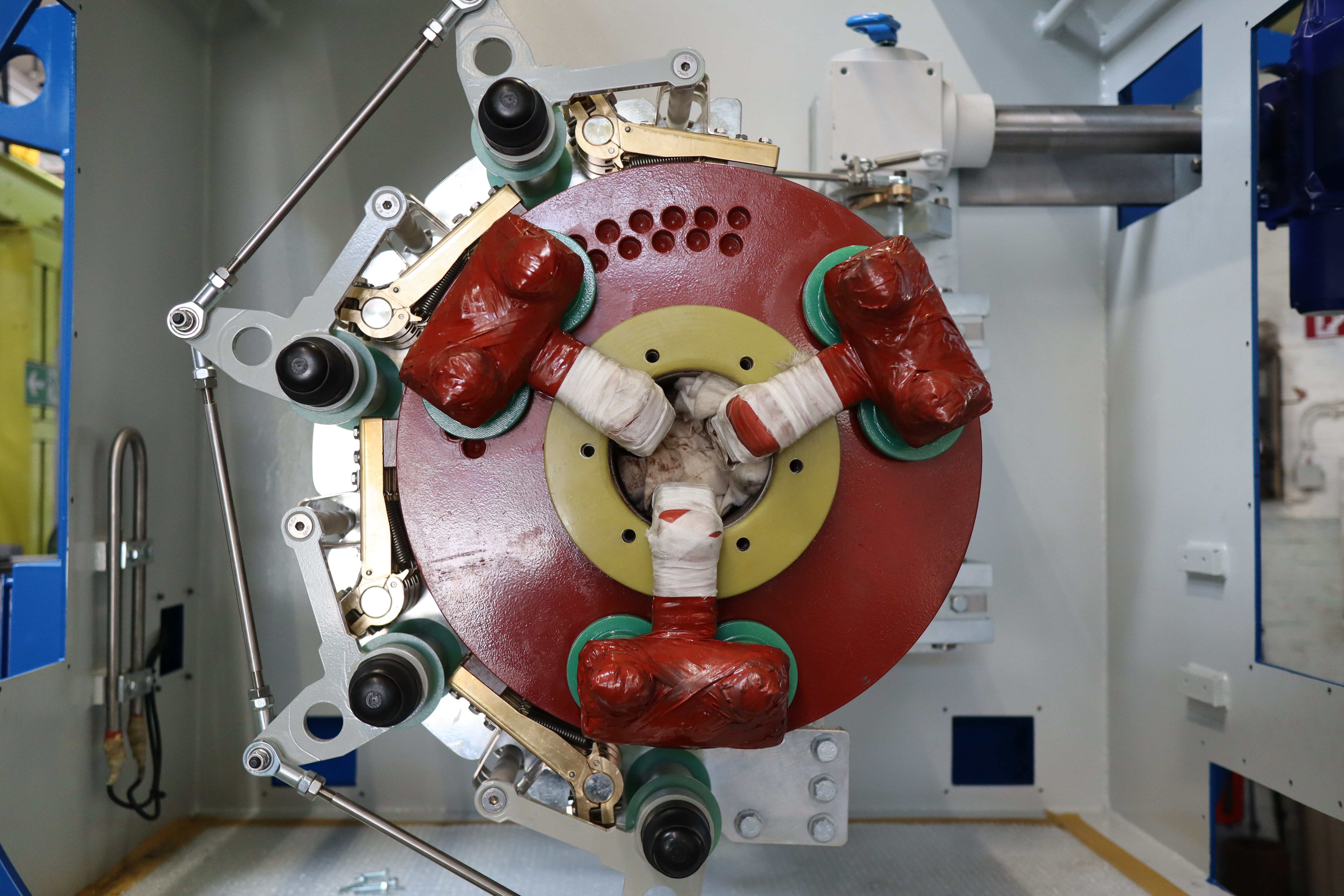

- 3-phase slip ring asynchronous motor with carbon brush lifting device (KBAV)

- Rated power: 6200 kW

- Rated voltage: 5000 V

- Standard: IEC / EN 60034-1

- Rated speed: 992 1/min

- Type: IM 1001 (IM B 3)

- Protection class: IP 55

- Cooling: IC 81W

- Weight: 24030 kg

New project film shows practical example

Our latest video accompanies the project with the State Water Utility in Baden-Württemberg:

The film summarises in three steps what MENZEL can offer you:

1: Development of a customised motor solution

Our highly qualified engineers analyse your requirements to develop exactly the motor solution you need ensuring smooth operation in your industrial plant. MENZEL manufactures and supplies customised three-phase asynchronous motors up to 13.8 kV and 25 MW as well as DC motors up to 1 kV and 2 MW.

E.g., the energy efficiency of the motor was particularly important to the customer. MENZEL therefore developed a solution with an efficiency of 96.7 %. In addition, we can supplement any particular motor solution with the necessary package of accessories and we manufacture special electric motors - for example the mentioned one with a short-circuit and brush lifting device, starter etc.

2: Removal of the old motor on site

Our experienced technicians will remove the existing motor to be replaced on your premises. This is done efficiently, reliably and in accordance with environmental regulations.

3: Delivery, installation and commissioning of the new motor

To ensure the desired result, all our motors are tested in our modern load test centre before delivery. As a customer, you are welcome to join us here to witness testing. Once the motor has been approved, it can be delivered worldwide thanks to our professional logistics management.

On request, MENZEL can - as in the project example - take over the installation and commissioning of all the associated motor components, including the alignment and commissioning of the new motor at your site. We also rely on the good work of our colleagues at Pawils Elektromaschinenbau GmbH, who completed the rewiring of the 5kV switchgear in the project with the state water supply company. With Pawils, we have a Full Service electrical contracting division at our side.

Specific enquiry? Write to us!

Do you need a complete electric motor solution or do you have another specific request?

Just contact us with the details at [email protected]

Specific motor solutions for OEM’s or end user‘s specified application

MENZEL is the electric motor supplier who can take care of all your electric motor requirements. Not only do we have one of the largest stocks of large industrial motors in Europe, but we are also available for a full range of services relating to the design, installation, alignment and commissioning of electric motors.

Below you will find a list of what we delivered on behalf of the mentioned customer:

- On-site measurement

- Delivery, installation and commissioning of a three-phase asynchronous motor in slip ring rotor design with brush lifting device

- Construction of a customised base frame

- Construction of a customised coupling

- Production, delivery, assembly, fine alignment and commissioning of the motor

- Manufacture, delivery and assembly of the appropriate liquid starter

- Testing of the motor and liquid starter at the manufacturer's factory

- Replacement of the entire power cabling between the existing 5 kV switch panel, the engine and the starter motor

- Dismantling and professional disposal of the existing motor

New motor plant from January 2024

All over the world, industrial customers rely on MENZEL motors when they need a reliable motor solution - even at very short notice. With almost 100 years of company experience under our belt, we will soon be moving to a new motor plant in Hennigsdorf (Berlin-Brandenburg). A completely new 24,000 m² production site is being built there.

The new motor plant will replace the current headquarters in Berlin-Moabit from January 2024. The 8,500 m² production area will house assembly, metalworking, winding, paint shop and test fields. There are also spacious offices, logistics zones and onsite motor storage areas.

You are welcome to find out about the current construction progress here.

Specific enquiry? Write to us!

Do you need a complete electric motor solution or do you have another specific request?

Just contact us with the details at [email protected]