Technical solution: Customization and integration

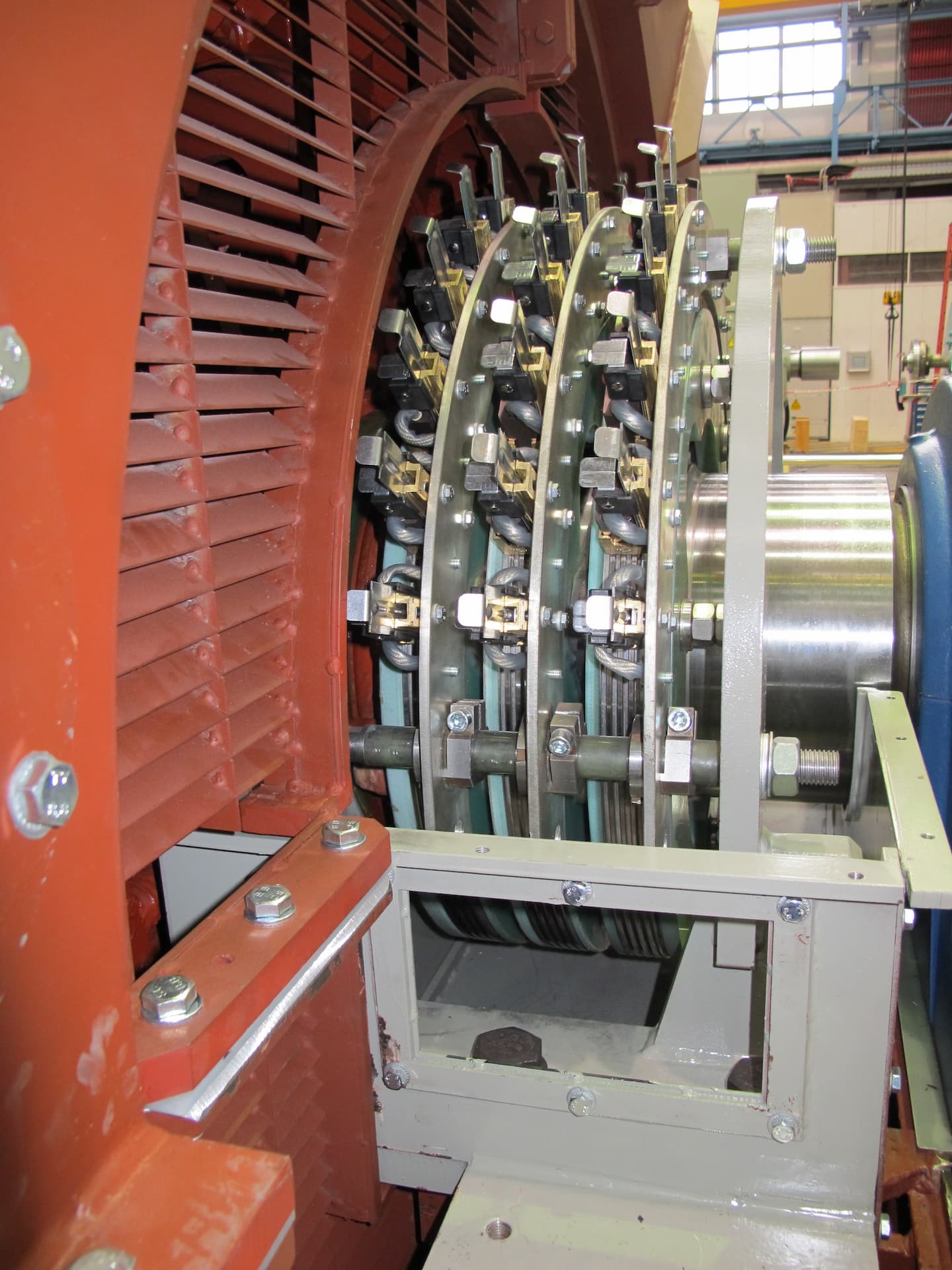

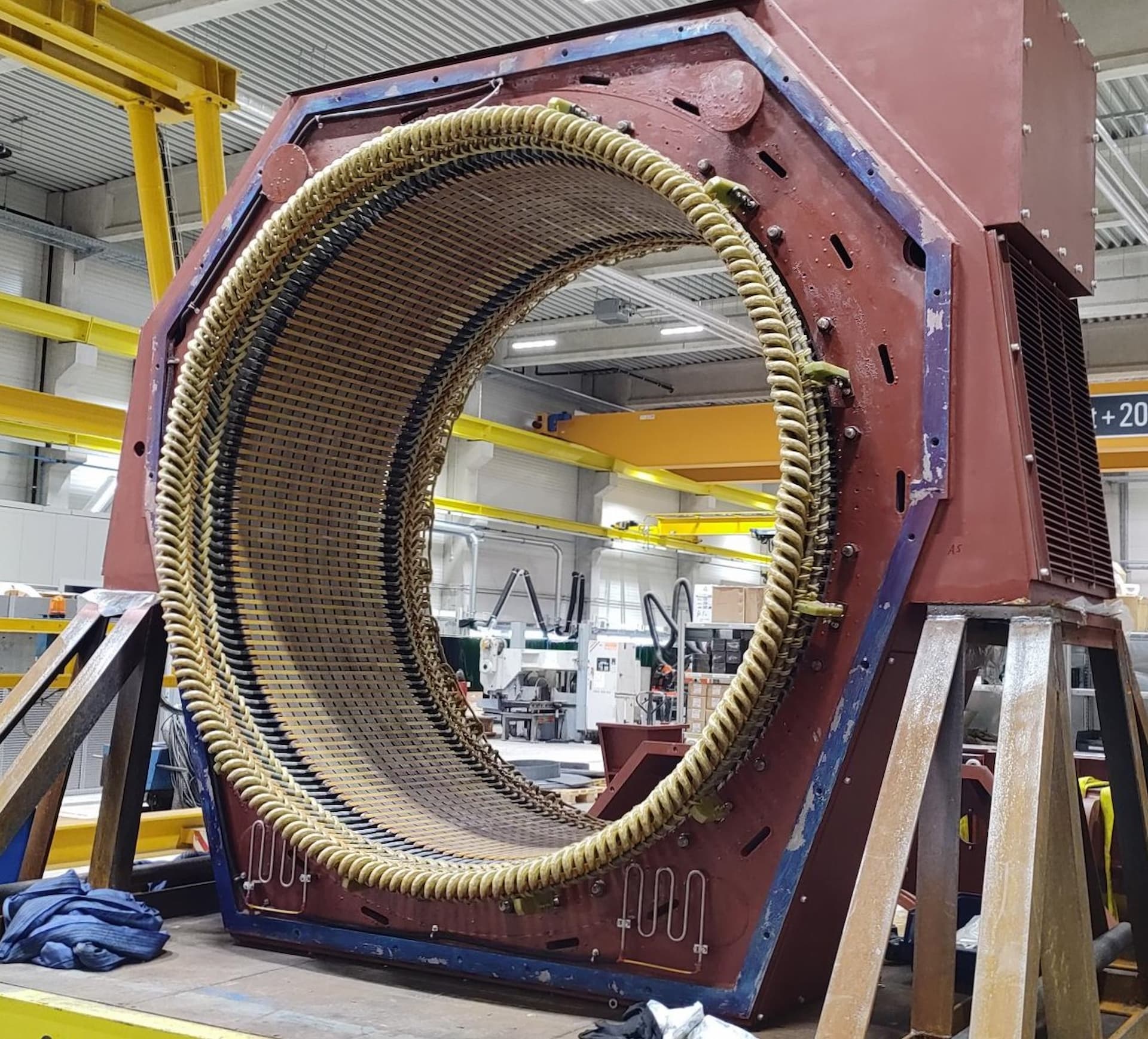

Menzel Elektromotoren designed a 20-pole slip ring motor in the rare IM 7311 design, which could be perfectly integrated into the existing system. The new motor delivers a rated power of 1345 kW operating at 6600 V achieving an impressive torque of 43245 Nm. With a total weight of 21.9 tons, including 10.4 tons for the rotor, a powerful and robust design was achieved.

The special equipment features included:

- HALL effect current transformers to measure the rotor current

- Acceleration sensors on the bearings (specified by the customer)

- A level sensor for the electrolyte of the associated liquid starter

In addition, the starter was designed so that it could be used for both the new motor and the old replacement motor.

Quality assurance: Comprehensive tests for maximum reliability

Before delivery, the motor underwent extensive type testing, which included additional tests according to customer specifications. These included partial discharge measurements and testing of the dissipation factor (tan δ). This ensured that the machine not only meets the highest standards, but also withstands the specific requirements of the harsh steel mill environment with ambient temperatures of up to 45 °C.

Securing Steel Production Efficiency

This project highlights the importance of modernizing industrial equipment while maintaining operational continuity. The new motor drives a roller unit in the steel factory with improved efficiency and reliability. Its higher capacity and torque (1345 kW / 1800 HP) secure and enhance steel production output.

Innovating for the Future

This project underscores MENZEL’s expertise in custom engineering for unique industrial applications. The company’s focus on non-standard solutions and ability to adapt to stringent client specifications sets a benchmark in the steel manufacturing industry. Looking ahead, Menzel anticipates an increasing demand for similarly complex motor designs like the IM 7311.

A success story

The nomination at the AEMT Awards honors the excellent engineering performance and customer-oriented approach of this project. With the combination of technical expertise, flexibility and the ability to meet complex requirements, Menzel Elektromotoren is setting a clear example for the future of drive technology.

If you are also looking for special motors for demanding industrial applications, contact us today!

Are you interested in further information or a customized motor offer? Send us your enquiry today!